Welcome

Welcome toBrakeMate Inc.?

We Work With You

It is our goal to build and maintain a strong, lasting relationship with our customers by giving superior customer service and support on top of providing the best forming equipment in the industry.

Sheet Metal Forming Equipment

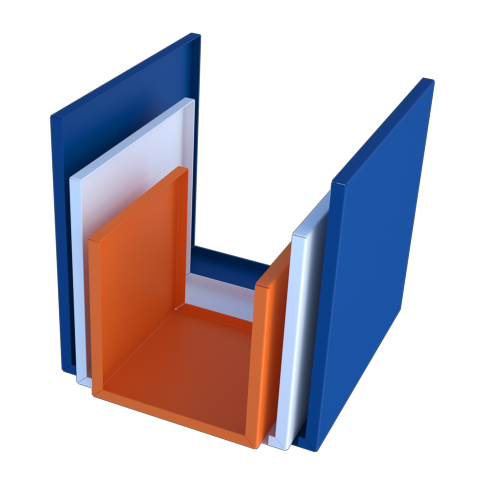

Forming tall panels, deep ‘u’ wrappers, and one-piece boxes are just some of the things that our machinery does STANDARD! If you find your production line spends too much time welding seams, we can eliminate that waste by forming those corners that simply can not be formed using a standard press brake. How do 7 seconds per bend sound? Can your press brake keep up with our wing bender?

Thank you for visiting our website and for your interest in BrakeMate Inc. If you would like more information on what we can do to automate your tedious forming tasks, please give us a call or see the contact page.

We look forward to working with you!

What is a Forming Machinery in Rockford IL?

Generally, people are not familiar with the word “forming”, which is pronounced “TAN-ATSU” in Japanese. In 1939, when the Ministry of Commerce and Industry of Japan intended to organize respective business fields and made the generic name “forming machinery” by taking initial characters of each forging machine, hammer, press machine, and press brake (press forming), etc. In general, forming machinery in Rockford IL means secondary metal processing machines such as metal processing machines and metal forming machines other than machine tools (machines to cut with tools). For your reference, primary metal processing machines produce steel stock and steel plates, while the secondary processing machines form products from steel plates made by the primary machines.

Metal processing and forming machinery covers a variety of types of machines.

The Benefits of forming machinery in Rockford IL

A forming machine bends metal at room temperature using a number of stations where fixed rollers both guide the metal and make the necessary bends. As the strip of metal travels through the roll forming machine, each set of rollers bend the metal a little more than the previous station of rollers. This progressive method of bending metal ensures that the correct cross-sectional configuration is achieved while maintaining the cross-sectional area of the workpiece. Typically operating at speeds between 30 to 600 feet per minute, roll forming machines are a good choice for manufacturing large quantities of parts or very long pieces.

Forming machinery in Rockford IL offers the user some specific advantages. Roll forming machines are energy efficient because they do not expend energy to heat material—the metal shapes at room temperature. Roll forming is also an adjustable process and is applicable to projects of varying time duration. Additionally, roll forming results in a precise, uniform part.

Roll Forming Machine Developments

Today’s roll forming machines feature computer-aided tooling designs. By incorporating CAD/CAM systems into the roll forming equation, machines function at their maximum potential. Computer-controlled programming provides roll-forming machines with an internal “brain” that catches product imperfections, minimizing damage and waste.

In many modern roll-forming machines, programmable logic controllers ensure accuracy. This is vital if a part needs multiple holes or needs to be cut to a specific length. The programmable logic controllers tighten tolerance levels and minimize accuracy. Some roll forming machines also feature laser or TIG welding capabilities. Including this option on the actual machine results in loss of energy efficiency, but removes an entire step in the manufacturing process.

Roll Forming Machine Tolerances

Dimensional variation of a part created through roll forming is based on the type of material used, the roll forming equipment, and the actual application. Tolerances can be influenced by varying metal thickness or width, material spring back during production, the quality and wear of the tooling, actual machine condition, and the experience level of the operator.