Welcome

Welcome toBrakeMate Inc.?

We Work With You

It is our goal to build and maintain a strong, lasting relationship with our customers by giving superior customer service and support on top of providing the best forming equipment in the industry.

Sheet Metal Forming Equipment

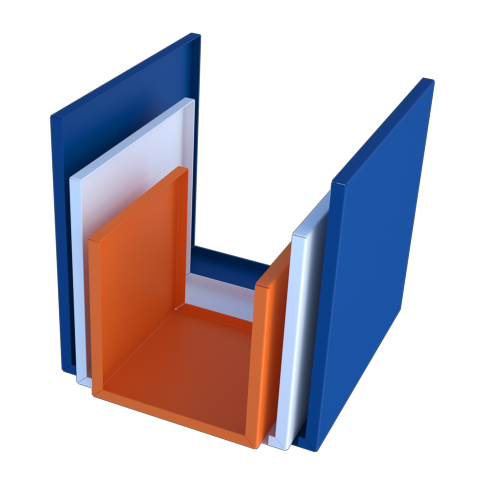

Forming tall panels, deep ‘u’ wrappers, and one-piece boxes are just some of the things that our machinery does STANDARD! If you find your production line spends too much time welding seams, we can eliminate that waste by forming those corners that simply can not be formed using a standard press brake. How do 7 seconds per bend sound? Can your press brake keep up with our wing bender?

Thank you for visiting our website and for your interest in BrakeMate Inc. If you would like more information on what we can do to automate your tedious forming tasks, please give us a call or see the contact page.

We look forward to working with you!

Roll Forming Machinery in Rockford, IL

Roll forming machinery in Rockford, IL, bend metal sheets into channels and also other cross-sectional shapes. They use paired rollers referred to as roll stations to type metal parts with lengthy lengths, often in large quantities. Roll-forming equipment utilized to shape steel can fabricate parts with higher strength-to-weight ratios than might be obtained through approaches such as forging.

Roll forming machines are utilized to fabricate rigid, high-strength components from metals as light as aluminum to as heavy as 6-gauge steel (1/2-in. thick). They may be utilized to make metal constructing components, studs, supports, angles, C-channels, U-channels, and hat channels.

Standards for Roll Forming Machinery in Rockford, IL

You’ll find several organizations that publish standards for roll forming and roll forming machines. For example, Technical Committee A01.19 (sheet and strip steel) of ASTM International (formerly called the American Society for Testing and Supplies) publishes requirements that apply to roll forming machinery. ASTM A568/A568M-05a can be a regular specification for sheet, carbon, structural, and high-strength, low-alloy, hot-rolled, and cold-rolled steel.

Machine Elements, Choices, and Accessories

Roll forming machinery in Rockford IL, typically include and incorporates power-driven bullet rollers, chain and gear drove rollers, rolling double-reel assistance stands, and emergency shut-off switches. Production alternatives could include hole-punching, notching, finishing, and bending. Some suppliers use a flower-shaped pattern to specify the successive stages of performance and the resulting or finish design and style. Accessories for roll forming equipment involve three-reel adapters, coil cradles, bottom rib roller assemblies, and run-out stands. Design and style software programs may enhance custom procedures and enable the simulation of those roll-forming processes through finite element analysis (FEA).

Some end-users of rolled merchandise require larger flatness requirements because of the use of machines that include laser cutters and high-speed punching centers. Roll forming machines could be essential to meet specifications on the resulting merchandise. For example, Common Motors North America publishes GMN11192, a typical for high-strength recovery annealed cold reduced sheet steel, a suitable product for roll-forming operations. The roll forming machinery in Rockford, IL manufacturer needs to comply with worldwide government business requirements. ISO is concerned with high-quality management and what the supplier does to ensure the customer’s high-quality requirements are met. Processes are in location beginning when the inquiry is received until even after the consumer receives the roll former and the follow-up procedure is accomplished.

The Price Tag of Roll Forming Machinery

Roll Forming Machine Price tag is based on the specifications with the profiles on the steel solution you want to produce. Before creating any decisions to start a brand new brand or expand your business, consider cautiously the under aspects to produce the ideal choice out of thousands of possibilities in the marketplace.