Welcome

Welcome toBrakeMate Inc.?

We Work With You

It is our goal to build and maintain a strong, lasting relationship with our customers by giving superior customer service and support on top of providing the best forming equipment in the industry.

Sheet Metal Forming Equipment

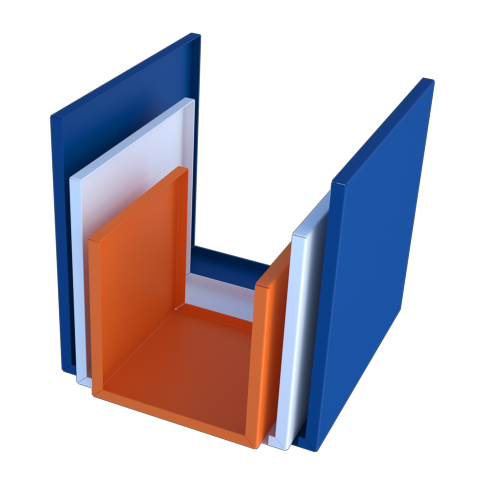

Forming tall panels, deep ‘u’ wrappers, and one-piece boxes are just some of the things that our machinery does STANDARD! If you find your production line spends too much time welding seams, we can eliminate that waste by forming those corners that simply can not be formed using a standard press brake. How do 7 seconds per bend sound? Can your press brake keep up with our wing bender?

Thank you for visiting our website and for your interest in BrakeMate Inc. If you would like more information on what we can do to automate your tedious forming tasks, please give us a call or see the contact page.

We look forward to working with you!

What Exactly is a Wing Bender Machine?

Bending metal into shape is a fundamental component of many industries. Whether it’s for art, practicality, or building construction, there are many reasons to bend steel. There are different types of machines that can do this work, and the wing bender machine is one such type. There are many different types of wing benders, depending on what type of material you want to bend and what size wings you need to make.

This blog post will go over the pros and cons as well as other information about wing bending machines so that when it comes time for your company to purchase one, you’ll know exactly which one is right for you!

Pros of a Wing Bending Machine

- Some companies use them to cut down on production costs. This can be a great option for companies that are trying to save money.

- They’re easy to operate and are self-contained, which means you can take them anywhere without having worries about the equipment being too big or heavy. This is particularly important if your company has employees who work at different locations on an as-needed basis.

- They produce consistent results.

- They’re versatile and can be used for more than just bending wing panels. Some manufacturers will also offer some machines that are designed specifically for other tasks, like making floor trays or customizing roofing shingles.

Disadvantages of a Wing Bending Machine

- A key disadvantage of a wing bending machine is that the limits are not as flexible. They typically take metal up to about an inch, so if your project needs something thicker than this then you can’t use them for it. You need to find another way around because they’re just too limited.

- It’s also difficult getting materials in and out of the machine because you’ll need to use a crane. This limits how many different materials can be used at once and makes handling difficult.

- If there are any irregularities or variations in metal thickness from one side of the sheet to another, then it limits what types of bends that they can make on your material.

In summary, wing bender machines are a great option for companies that have limited space and want to save money. They’re easy to operate, versatile, and produce consistent results. For more information about this product or if you would like some help finding the best one suited for your needs contact us today!