Welcome

Welcome toBrakeMate Inc.?

We Work With You

It is our goal to build and maintain a strong, lasting relationship with our customers by giving superior customer service and support on top of providing the best forming equipment in the industry.

Sheet Metal Forming Equipment

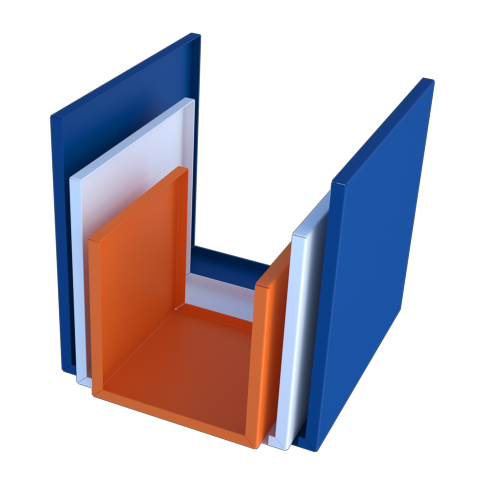

Forming tall panels, deep ‘u’ wrappers, and one-piece boxes are just some of the things that our machinery does STANDARD! If you find your production line spends too much time welding seams, we can eliminate that waste by forming those corners that simply can not be formed using a standard press brake. How do 7 seconds per bend sound? Can your press brake keep up with our wing bender?

Thank you for visiting our website and for your interest in BrakeMate Inc. If you would like more information on what we can do to automate your tedious forming tasks, please give us a call or see the contact page.

We look forward to working with you!

The Use of Metal Forming Machine in Rockford

In metal forming tools, the enhancement of properties for example hardness, coefficient of friction, and high strain make contact with fatigue resistance is of paramount value for enhancing productivity and extending tool life.

In applications where the high Hertzian get in touch with stresses are involved in metal forming operations, hardness from the nitride layer, as well as hardness from the tool underneath it, must be enough to resist those situations.

It can be critical to creating a positive that the nitride layer having such high hardness doesn’t have any network of carbonitrides or uncontrolled white layer thickness. As previously explained, not possessing a suitable structure may possibly lead to a premature failure from the tool. Microstructure on the layer in M-2 steel tuned up for forming applications.

Metal Forming Machine Tools in the Market

Metal forming machine in Rockford would be the needed tools employed in the manufacturing and automobile sector. Metal forming can be described because of the deformation of the metal to any necessary shape with no loss of raw components. It essentially consists of stamping machines, pressing, bending, and shearing machines. The marketplace improvement of the metal shaping machine course of action is in all probability going to profit inside the upcoming years in particular, in the assembling segment. It may be divided into two varieties i.e. Bulk-forming and Sheet forming. The basic difference involving the two is the bulk-forming is performed in enormous operations and when Sheet forming is accomplished through cutting sheets. They want to make higher precision solutions acts to become a major element inside the improvement of metal forming machine in Rockford tools.

Primary Impacting Factors: Industry Scenario Evaluation

The boost within the awareness of automation and high precise metals are becoming the main growth drivers for the Metal Forming Market tools. Further, the rise inside the growth of fabricated machines in the automobile industries, building industries, and electronics market has pushed up the metal forming machine tools market. Nowadays bending machines are in high demand which can be also a part of metal forming machine tools. Asia-Pacific areas like India, China, Indonesia, and Japan are rapidly rising their infrastructure projects which also act as a major essential element for the growing requirement of metal forming machine tools. Asia-Pacific area is a developing region and about to lead the industry in close to future. North America region getting the largest industry within the manufacturing and supplying of these tools followed by Europe because the major crucial players are based from this region.

The High investments across diverse infrastructural and technological components have empowered makers of metal forming machine in Rockford to provide high excellent items for the end-users and meet the higher demand. On the other hand, the high initial investment and improved application of non-metals like plastics and fiber items hinder the market development. Contrarily, the requirement for metal forming machine tools in the automotive business, Railways, customer durables, and engineering present new opportunities within the sector. The requirement for these tools in the automotive possess a higher demand followed by the consumer durables plus the railway division in particular for the rail tracks present new pathways for these machine tools.