Welcome

Welcome toBrakeMate Inc.?

We Work With You

It is our goal to build and maintain a strong, lasting relationship with our customers by giving superior customer service and support on top of providing the best forming equipment in the industry.

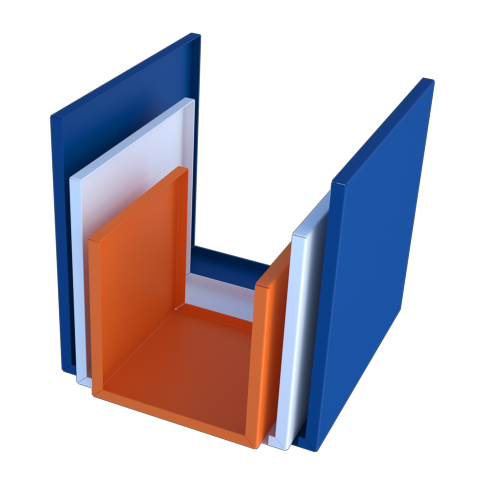

Sheet Metal Forming Equipment

Forming tall panels, deep ‘u’ wrappers, and one-piece boxes are just some of the things that our machinery does STANDARD! If you find your production line spends too much time welding seams, we can eliminate that waste by forming those corners that simply can not be formed using a standard press brake. How do 7 seconds per bend sound? Can your press brake keep up with our wing bender?

Thank you for visiting our website and for your interest in BrakeMate Inc. If you would like more information on what we can do to automate your tedious forming tasks, please give us a call or see the contact page.

We look forward to working with you!

The Advantages and Disadvantages of the Dual Head Former

When you are looking for a bender that can bend both head and sheet metal, there are really only three options. A dual-head wing bender is one of the most popular choices as it provides more flexibility than a tangent bender. The main advantage to using a dual head former is the ability to use two heads at once. This means that you can produce twice as many bends in half the time with the same amount of effort! But before making this purchase, be sure to consider other factors such as maintenance and material compatibility.

Advantages of a Dual Head Wing Bender

- Dual head former is a great option for beginners.

- With dual head forming, you get the benefits of both manual and automatic benders without having to buy two machines.

- Produces parts that are more consistent in thickness and shape because you have two heads operating at different speeds.

Disadvantages of a Dual Head Former

- The dual-head former requires a lot of floor space, which can be difficult to find in some plants.

- Dual head formers have more moving parts than single heads and require regular maintenance.

To help you explore the advantages and disadvantages of a dual-head former, we’ve created this brief overview. We hope it helps you to make an informed decision about whether or not one is right for your company! Would you like more information on how a dual-head former can benefit your business? If you have any questions please contact us today, our team would be happy to answer all of them.