Welcome

Welcome toBrakeMate Inc.?

We Work With You

It is our goal to build and maintain a strong, lasting relationship with our customers by giving superior customer service and support on top of providing the best forming equipment in the industry.

Sheet Metal Forming Equipment

Forming tall panels, deep ‘u’ wrappers, and one-piece boxes are just some of the things that our machinery does STANDARD! If you find your production line spends too much time welding seams, we can eliminate that waste by forming those corners that simply can not be formed using a standard press brake. How do 7 seconds per bend sound? Can your press brake keep up with our wing bender?

Thank you for visiting our website and for your interest in BrakeMate Inc. If you would like more information on what we can do to automate your tedious forming tasks, please give us a call or see the contact page.

We look forward to working with you!

Roll Forming Using a Dual Head Former

Roll forming, also spelled roll-forming or rollforming, is usually a form of rolling involving the continuous bending of a lengthy strip of sheet metal (commonly coiled steel) into a preferred cross-section. The strip passes through sets of rolls mounted on consecutive stands, each and every set performing only an incremental part of the bend until the desired cross-section (profile) is obtained. Roll forming is perfect for creating constant-profile parts with long lengths and in substantial quantities.

Value of Roll Forming Machine

Roll forming machine is usually a widespread gear that produces metal profiles in a variety of shapes. The shape with the profile is dependent upon the roller set or rolling tool, which is the heart of the roll forming machine.

Roll forming machine is definitely an important element for human development. It assists men and women make fantastic progress in the steel structure field that is the symbol of human modernization. Roll forming is actually a continuous and automatic production compared to press brake and shear gear. Furthermore, it integrates quite a few other metal processes so as to enhance human productivity.

Roll forming machines are also good for developing precise parts that require quite small, if any, finishing performance. In most situations, depending upon the material becoming shaped, the end solution capabilities a great finish and really fine detail.

Rollers

The rolls or rollers are created of round steel and processed with distinct therapy based on diverse technical needs. Roller would be the heart of a roll-forming machine. In practical terms, rollers manufacturing has to be exceptionally precise. The deviations of roundness or eccentricities of an incredibly low order will drastically affect the high quality or accuracy of the completed goods. Besides, the surface therapy has to be exceptionally higher because of the get in touch with and lubrication problems. Normally, rollers are split into quite a few sections for very simple manufacturing. As a matter of fact, there are situations that prove it is also necessary for easier assembling.

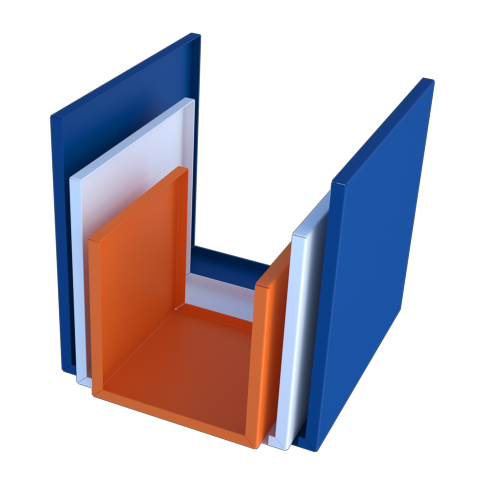

Dual Head Former

The Dual Head former is created to type two (2) edges with the strip or component in the identical time inside a single pass via operation. The Dual Head former provides a rapid changeover notion for components requiring a wide array of widths. It can be made use of as an absolutely free-standing blank fed unit or adapted into a coil feed application. A dual head former is mostly employed on edge forming operations requiring straight parallel formed edges like Shelving, Cabinets, and Wall Panels.

As in all roll form applications, the element perimeters will establish the size, centers, spindles, and horsepower required. Using a dual head former not only is definitely the quality with the Spindle Housings (Forming Heads) significant but also the alignment and parallelism on the heads and how the slide and Drives are configured.