Welcome

Welcome toBrakeMate Inc.?

We Work With You

It is our goal to build and maintain a strong, lasting relationship with our customers by giving superior customer service and support on top of providing the best forming equipment in the industry.

Sheet Metal Forming Equipment

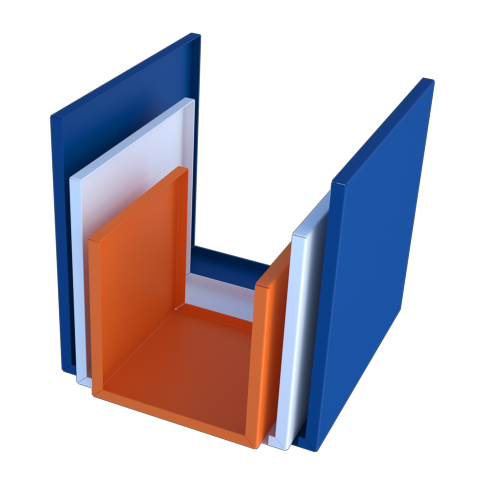

Forming tall panels, deep ‘u’ wrappers, and one-piece boxes are just some of the things that our machinery does STANDARD! If you find your production line spends too much time welding seams, we can eliminate that waste by forming those corners that simply can not be formed using a standard press brake. How do 7 seconds per bend sound? Can your press brake keep up with our wing bender?

Thank you for visiting our website and for your interest in BrakeMate Inc. If you would like more information on what we can do to automate your tedious forming tasks, please give us a call or see the contact page.

We look forward to working with you!

Metal Forming Machine in Rockford Cutting Techniques

Metal forming machine in Rockford is really a machine that does form processes not by traditional cutting but deforming techniques on the perform pieces materials. This approach does not add or take away the existing supplies, as well as the forming perform pieces stay unchanged concerning their physical mass.

Around the other side, if it is a drill press or punch machine, then many of the function piece components are changed as reduce by metal dies but the reduced element nevertheless remains unchanged by its existence.

Inventory of Metal Forming Machines

There are many unique kinds of metal forming machine in Rockford in the metal functioning sector, for instance, forging forming, casting forming, tube bending, bar bending, sheet welding, pipe welding, die-cutting, punch cutting, reduce to length, and lots of other metal forming machines. Relating to the industrial applications of these metal forming machines, there are several of them are applied to furniture, sports, consumer electronics, and household appliances.

Inside the making of cutting pieces, the size with the forming die determines the corresponding sizes of the press machines to become utilized. To be precise, forming units which include hydraulic press has been classified into various categories, which include hydraulic deep drawing press, hydraulic try-out press, as well as other cutting, die forming machines.

If compared with other press machines including try-out press and ordinary metal forming machines, the mechanical force of hydraulic press machines could be substantially stronger than other folks, simply because the key task of this type of machine is to make forms on the perform pieces no matter of its material essences. Additionally, since traditional press forming machines are responsible for the actual and enormous production of items, the mechanical strength is just not only confined to the forces, but also to much other cutting and forming specifications.

Metal Forming Processes

Metal forming processes are an important part of our society, and without no them, our society would come to a grinding halt.

The items and elements created by the different metal shaping strategies are made use of in making all the things from scaffolding and heavy machinery, to designing and producing microprocessors and artificial intelligence.

In terms of metal forming, there are several processes to choose from, with every offering its personal list of rewards and detriments, each suited to particular applications, and every suited for distinct kinds of metal.

Metal Roll Forming and Reduce to Length Lines

Reduce to length lines are normally coupled with metal forming machine in Rockford to create the production approach integrated. A cut to length line is actually a popular approach to making flat, rectangular blanks from larger metal coils. This system can also be referred to as a CTL or perhaps a blanking line, and a lot of suppliers’ cut to length machines will uncoil the bigger material or master coil, straighten or flatten it, then cut it for the expected length as it moves through the metal roll forming lines.

Besides these forming strategies, you can find nonetheless other machines that can do the metal forming approach without considerably higher-finish technology but with higher stability and productivity. It’s said that if quite a few cutting processes are often created to a course of action just like press punch, then the metal functioning will be easier in quite a few aspects.